Traditional MOV Limitations: MOV7D561K’s Old-Era Bottleneck

MOV7D561K: A Classic Through-Hole Component

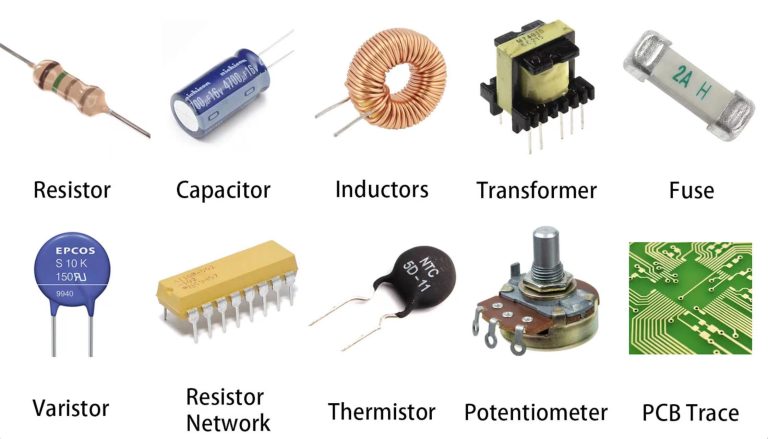

Metal Oxide Varistors (MOVs) have long been the mainstream for surge protection. MOV7D561K—a 7 mm disc-type MOV in THT format—is widely recognized in India for its popularity and low unit cost.

But as electronics demand miniaturization, efficiency, and reliability, traditional THT technology represented by MOV7D561K is increasingly a bottleneck to innovation.

From manufacturing to design:

- THT relies on manual or semi-auto insertion plus wave or hand soldering—leading to higher labor costs, longer cycles, and lower efficiency.

- SMT lines can place tens of thousands of components per hour (10–20× faster), offering the automation that the Indian market needs.

- THT parts like MOV7D561K use much PCB space due to size and drill holes. SMT allows dual-side placement—enabling denser, smaller layouts.

- THT leads introduce parasitic inductance, delaying response and increasing clamping voltage—reducing protection effectiveness. Relying solely on low component price ignores the high total cost of ownership—from rework, labor, and inefficiency.

CMS1206V511: A New Surge Protection Benchmark for SMT

SMT-meets-design fusion:

Boarden’s CMS1206V511 series—plastic-encapsulated, multilayer ceramic MOVs—heralds a new age in SMT-based surge solutions. Key advantages:

- Manufacturing Efficiency: Tape-and-reel packaging (2,000 pcs/reel) perfect for automated pick/place and reflow—boosting efficiency by 10–20× and reducing labor.

- Space Efficiency: Compact 3.2 × 1.6 mm footprint versus traditional 7 mm, with dual-side SMT placement enabling much smaller yet powerful board design.

Performance Deep Dive: CMS1206V511 vs MOV7D561K

| Feature | CMS1206V511P500-E (SMD) | MOV7D561K (THT) | Advantage |

|---|---|---|---|

| Package | 1206 SMD (3.2×1.6 mm) | 7 mm Disc THT | Saves board space, SMT friendly |

| Max Continuous Voltage (Vac) | 410 V | 350 V | Better tolerance to voltage variations |

| Varistor Voltage (V@1 mA) | 459–561 V | ~560 V | Similar baseline protection |

| Max Clamping Voltage (Vc) | 840 V @ 5 A | ~920 V @ 10 A | Lower clamping → better downstream safety |

| Peak Surge Current (8/20 μs) | 150 A | 1.2–1.75 kA | Designed for precision protection, not bulk |

| Max Energy (10/1000 μs) | 1.3 J | 30–35 J | Different design philosophy |

| Operating Temperature Range | −55 °C to 125 °C | −40 °C to 85 °C | Better heat tolerance for hot climates |

CMS1206V511 clamps transients to ~840 V—much lower than MOV7D561K’s ~920 V—thus offering more reliable protection. Though MOV7D561K handles higher surge current and energy, CMS is engineered as an ultra-fast, last-mile protection, ideal for multi-stage protection strategies.

Why CMS1206V511 Excels

- Zero Lead Inductance & Ultra-Fast Response: SMT design removes lead inductance, enabling nanosecond-level protection—crucial for sensitive, high-speed circuits.

- Wide Thermal Tolerance for Indian Climate: From –55°C up to 125 °C (no derating at max temp), CMS withstands harsh heat better than MOV7D561K, which maxes at 85 °C.

- Multilayer Ceramic Structure: High power dissipation and mechanical robustness preserved in micro size—excellent surge absorption.

Tailored for Indian Market

CMS1206V511 aligns with India’s needs by delivering:

- Lower clamping voltage and faster response to common surges and fluctuations.

- Compliance with IEC61000-4-5, UL, cUL, and TUV—enabling global market access.

- A shift from manual THT towards automated SMT—delivering lower cost, higher throughput, improved design flexibility, and better reliability. Boarden becomes not just a supplier, but a growth enabler.

Conclusion

Boarden’s CMS1206V511 series is a revolutionary replacement for MOV7D561K—delivering superior protection, SMT efficiency, and climate resilience. It helps manufacturers reduce cost, accelerate time-to-market, and enhance competitiveness.

Contact Boarden to request CMS1206V511 datasheets, samples, expert support, and to see its effective role in your SMT line.