Electrification Challenges in Modern Two-Wheelers

The two-wheeler industry is evolving rapidly, with motorcycles and electric two-wheelers becoming increasingly sophisticated. ECUs (Electronic Control Units), full LED lighting, USB charging ports, smart dashboards, and advanced communication modules are now standard features. This enhanced functionality brings a more complex electrical system, facing unprecedented environmental and electrical threats.

Invisible hazards like overvoltage, transient surges, motor interference, ESD (Electrostatic Discharge), and reverse polarity connections are constant threats. These can lead to severe consequences: ECU failure, reduced LED lifespan, or even complete control system malfunction. Therefore, implementing a systematic motorcycle and two-wheeler circuit protection solution is no longer optional. It is crucial for ensuring vehicle reliability, enhancing safety, reducing after-sales maintenance costs, and boosting brand competitiveness.

Understanding the Differences: Fuel Motorcycles vs. Electric Two-Wheelers

Effective circuit protection design begins by understanding the fundamental electrical differences between these two platforms. This dictates the primary threats and the focus of protection strategies.

- Fuel Motorcycles (ICE Platform): Typically operate on a 12V system, powered by an AC alternator and regulator-rectifier. Primary electrical risks include regulator-rectifier failure, high voltage transients from ignition coil operation, and inductive surges from components like cooling fans and relays.

- Electric Two-Wheelers: Feature a more diverse range of voltage platforms (e.g., 24V, 36V, 48V, 60V, 72V), powered directly by the battery bus through a motor controller/DC-DC converter. Risks are concentrated on dv/dt interference from high-speed motor controller switching, bus voltage elevation due to regenerative braking or load dumps, and surge/ESD events at charging ports.

Key Electrical Threats to Two-Wheeler Electronics

Common Threats in Fuel Motorcycles

- Sustained Overvoltage: A common, destructive event where regulator-rectifier failure causes bus voltage to remain above 16V, often reaching tens of volts. This is a primary cause of ECU damage and LED driver burnout.

- Transient Surges: Intermittent operation of ignition coils, along with the start/stop cycles of relays and motors, generates sharp voltage spikes. These can cause ECU resets, sensor malfunctions, or permanent damage without adequate motorcycle surge protection.

- ESD (Electrostatic Discharge): Daily interactions such as touching USB ports, dashboard buttons, or diagnostic ports during maintenance can introduce ±8kV to ±15kV ESD events. Such high-voltage, low-energy pulses can easily damage sensitive interface chips.

- Reverse Polarity/Short Circuit: Accidental misconnection during battery replacement or jump-starting can lead to immediate high current flow, causing irreversible damage to unprotected electronic components.

Common Threats in Electric Two-Wheelers

- Bus Voltage Elevation: During regenerative braking or sudden load shedding, the DC bus voltage can momentarily surge, potentially triggering controller protection or damaging power devices. This requires robust electric scooter overvoltage protection.

- PWM Spikes & Common-Mode Interference: High-speed switching of the inverter within the motor controller generates significant dv/dt interference. This noise can couple into wiring harnesses, disrupting communication and HMI modules.

- Charging Port Surges & Lightning Strikes: A unique high-risk area for electric two-wheelers. External charging equipment can introduce power surges or even lightning-induced transients, exposing the charging port and communication lines to high-energy pulses.

- ESD & EFT (Electrical Fast Transients): Beyond typical ESD, peripheral interfaces, HMI screens, and communication ports are susceptible to EFT coupling. These rapid, repetitive pulses can cause system freezes or malfunctions.

Layered Circuit Protection Strategies for Two-Wheelers

A successful two-wheeler circuit protection design goes beyond simply adding components; it adheres to a systematic, multi-layered defense strategy.

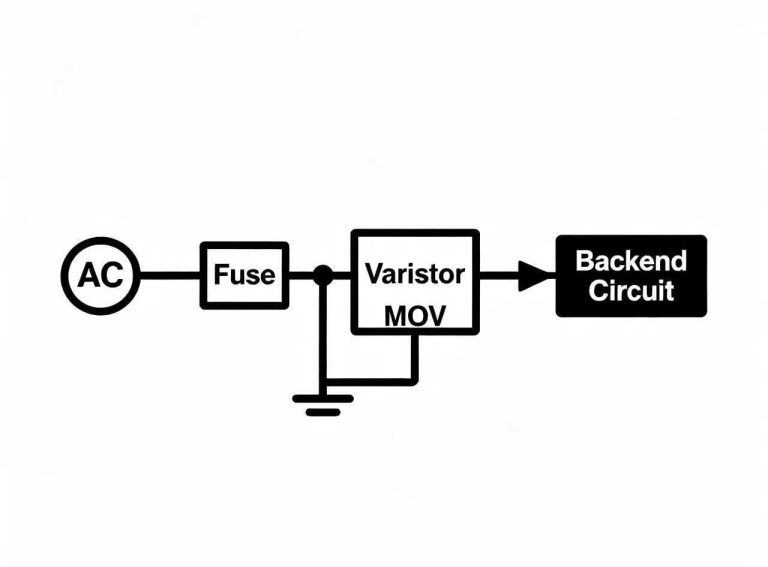

First Line of Defense: Power Input Robustness

The power input serves as the primary barrier against high-energy external impacts.

- For Motorcycles: Parallel connection of a high-energy CMS MOV varistor or a large power TVS diodeat the regulator-rectifier output is crucial. These devices absorb high-energy overvoltage pulses resulting from regulator failure. This is key for motorcycle ECU protection.

- For Electric Two-Wheelers: Implement an MOV + high-voltage TVS combination at the battery bus and charging port. For charging ports in high lightning risk areas, adding a GDT (Gas Discharge Tube)can provide primary discharge of extreme energy.

Second Line of Defense: Core Module Shielding

- Install a fast-response TVS diode at the power input of high-value modules such as the ECU, LED drivers, dashboards, and DC/DC converters. This provides secondary, precise voltage clamping, ensuring the voltage entering the module is absolutely safe.

- Design Considerations: For 12V systems, TVSs with 16–24V breakdown voltage are common. For 48–72V systems, higher voltage models with sufficient energy absorption margin are necessary. A π-type filter structure, combining a series bead or small resistor with a TVS, further enhances surge protectioncapabilities.

Third Line of Defense: External Interface Guardians

- Dedicated ESD suppressors are essential for all external data and control interfaces, including USB, CAN, LIN, and UART ports.

- Design Considerations: The critical parameter here is low capacitance (e.g., ≤1pF for high-speed interfaces like USB) to maintain signal integrity. ESD devices should be placed as close as possible to the connector to provide the shortest discharge path.

Internal Interference Suppression

- For inductive components like relay coils, solenoids, and fan motors, parallel connection of flyback diodes, RC snubber networks, or TVS diodes at their terminals is vital. This suppresses voltage spikes generated during their switching cycles, preventing internal noise propagation.

Component Selection & Layout Best Practices

- TVS Diodes: Select a TVS with a Reverse Standoff Voltage (Vrwm) slightly above the circuit’s maximum operating voltage, ensuring its Clamping Voltage (Vc) remains below the protected chip’s absolute maximum rating. Layout should be as close as possible to the protected target.

- CMS MOV Varistors: Ideal for high-energy absorption at power inlets. Consider their lifespan under continuous operating temperatures. Boarden offers various packages, including 0603, 0805, 1206, and 2220, balancing compact size with robust surge protection.

- ESD Suppressors: Prioritize ultra-low capacitance models (<1pF) for high-speed interfaces. Place them right next to the connector and ensure short, wide ground traces to prevent on-board discharge.

- GDT Gas Discharge Tubes: With a slower response, GDTs are generally not for internal low-voltage DC system protection. However, their high current handling capability makes them excellent primary protection for charging ports or long cable runs prone to lightning strikes.

- Grounding & Thermal Design: Employ single-point or zonal grounding strategies. For power components like TVS/MOV, ensure large copper pour areas underneath for effective heat dissipation. Maintain adequate creepage and clearance distances according to voltage levels.

Testing & Standard Compliance

- Fuel Motorcycles: Typically require testing to ISO 7637-2, which simulates critical transients like load dump, ignition interference, and general surges.

- Electric Two-Wheelers: Compliance with international standards such as IEC 61000-4-2 (ESD), IEC 61000-4-4 (EFT), and IEC 61000-4-5 (Surge) is crucial for comprehensive protection.

- Company-Level Validation: Testing should cover worst-case operational scenarios, including cold starts, regenerative braking events, ignition interference, and fan start/stop cycles, to ensure overall vehicle reliability.

Boarden: Your One-Stop Circuit Protection Solution

Boarden Electronics offers a comprehensive motorcycle and two-wheeler circuit protection solution. Our extensive product line includes:

- CMS MOV Varistors: Compact yet highly energy-absorbent, ideal for power input and bus overvoltage suppression.

- TVS Diodes: Available across a wide range of voltage ratings, perfectly suited for both 12V and 48–72V platforms.

- ESD Suppressors: Ultra-low capacitance series, perfectly designed for high-speed USB and communication interfaces.

- GDT Gas Discharge Tubes: Providing high-energy lightning protection for charging ports and long cable applications.

All our products comply with stringent automotive-grade standards like AEC-Q200 and ISO 7637. We have a proven track record of successful mass production applications in major motorcycle and electric two-wheeler markets across India, Southeast Asia, and globally.

To discuss your design challenges or request free samples and technical support, please add WeChat 4027704 (remark: Two-Wheeler Circuit Protection) and join our engineer discussion group.