Resistor Types

Resistors are among the most fundamental and commonly used components in electronic circuits. Whether in consumer electronics, lighting systems, industrial automation, or power supply modules, resistors are found on nearly every circuit board. Understanding the principles, types, and applications of various resistors helps engineers make better design decisions and improves the overall reliability and safety of electronic systems.

As a specialized supplier of circuit protection components, Boarden focuses on varistors (MOV, MLV), TVS diodes, GDTs, PPTCs, and fuses. This article outlines the essential classifications, characteristics, and practical applications of resistors in the context of Boarden’s product offerings.

I. Basic Operating Principle of Resistors

Resistors limit the flow of electric current and control voltage and current distribution in a circuit. Key parameters include:

- Resistance Value (Ω): Determines how much the resistor impedes current.

- Rated Power: The maximum power a resistor can handle continuously.

- Tolerance: The acceptable deviation between the actual and nominal resistance value.

- TCR (Temperature Coefficient of Resistance): Indicates how the resistance value changes with temperature.

Using Ohm’s Law (V = I × R), engineers can calculate voltage and current distribution within a circuit.

II. Main Types of Resistors

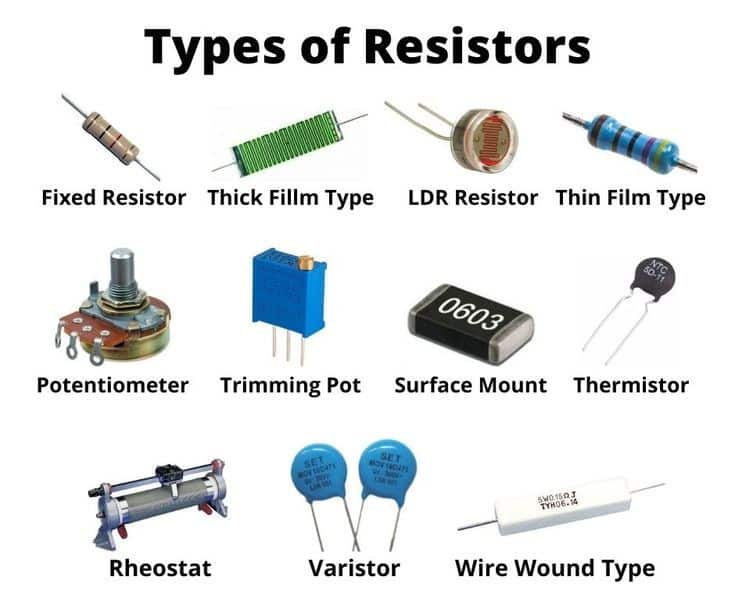

1. By Material:

- Carbon Film Resistors: Low cost, moderate stability; used in general applications.

- Metal Film Resistors: High precision, low temperature drift; ideal for precision control circuits.

- Metal Oxide Resistors: High temperature tolerance; used in industrial circuits.

- Wirewound Resistors: High power handling and thermal stability.

- Varistors (MOV/MLV): Sensitive to overvoltage; primarily for surge protection.

2. By Packaging:

- Through-Hole (DIP): Suitable for traditional PCB soldering; easy to replace.

- Surface Mount (SMD): Compact size; ideal for automated SMT production.

- Special Packages: Resistor networks, potentiometers, and adjustable types.

3. By Function:

- Fixed Resistors: Have a constant resistance value.

- Variable Resistors: Adjustable resistance for tuning or control purposes.

- Characteristic-Based Resistors: React to environmental conditions like temperature or voltage (e.g., NTC/PTC thermistors, MLVs).

III. Spotlight on MLV Varistors and Surge Protection

Multilayer Ceramic Varistors (MLVs) are chip-type devices designed for surge suppression. Under normal voltage, they remain in a high-resistance state. When voltage exceeds a threshold, they rapidly conduct, clamping the surge and protecting downstream circuits.

Compared with traditional Metal Oxide Varistors (MOVs), MLVs offer:

- Smaller size, suitable for high-density SMT assemblies.

- Faster response, making them ideal for sensitive electronics.

- Better suited for low-energy surge protection, such as in LED drivers and compact power supplies.

Boarden’s CMS series of MLV varistors support various sizes (0603–3225), operate reliably under high temperatures, and meet global certifications like BIS and UL. They are widely used in smart lighting, consumer electronics, power modules, and industrial control.

IV. Typical Applications of Resistors

| Application Field | Recommended Type | Key Features |

|---|---|---|

| LED Drivers | MLV Chip Varistors | Compact, surge protection, heat resistant |

| Power Supply Modules | MOV / TVS + Resistor Combo | High energy absorption, fast response |

| Industrial Control | Metal Oxide Resistor / MOV | High stability, voltage & heat tolerance |

| Consumer Electronics | SMD Precision / PTC | Compact, safe, and circuit-friendly |

| Transformer Front-End | Wirewound + GDT | Excellent surge endurance |

V. Reliability and Failure Modes of Resistors

1. Derating Design

To extend service life, resistors should be used at 60–70% of their rated power in real-world applications.

2. Common Failure Modes

- Resistance drift

- Thermal failure (burnout)

- Breakdown or short circuit

3. Reliability Testing

Common tests include withstand voltage, thermal cycling, temperature shock, and high-temperature aging. High-reliability components may also require UL, AEC-Q200, or similar certifications.

Boarden Product Recommendation & Selection Support

Understanding resistor types, structure, and performance enables engineers to make smarter design choices for greater circuit safety and reliability. Boarden continues to deliver trusted circuit protection solutions to support your product stability and long-term performance.

Boarden provides a complete line of certified varistor products, including CMS series, BIS-compliant models, and high-energy plugin surge protectors.

Our engineering support includes:

- Surge level evaluation

- Parameter calculation and simulation

- Customized packaging and specifications

For selection sheets, sample requests, or technical assistance, please contact us for more informations.