Difference Between a Fuse and a Varistor

In electronic circuit design, overcurrent and overvoltage are two fundamental risks. The fuse and the varistor (MOV, Metal Oxide Varistor) are the most widely used components to address these challenges.

Although both aim to improve circuit safety, their working principles, selection criteria, and applications differ significantly. This article explains their roles, how they work together, and practical selection guidelines for engineers.

Fuse in Overcurrent Protection: How It Works and Key Parameters

A fuse is designed for overcurrent protection and is connected in series within a circuit. When current exceeds its rated value for a certain duration, the fuse wire melts due to Joule heating, disconnecting the circuit and protecting downstream components. This is a one-time, non-recoverable protection.

Rated Current and Rated Voltage

- Rated Current: Maximum current a fuse can safely carry under normal operation.

- Rated Voltage: Maximum voltage the fuse can safely withstand after breaking.

Fast-Acting vs Time-Lag Fuse

- Fast-acting fuses: Protect sensitive electronics.

- Time-lag (slow-blow) fuses: Withstand inrush currents from power supplies or motors.

I²t Value (Melting Integral)

Defines the energy needed to melt the fuse, ensuring immunity against short surges and preventing nuisance tripping.

⚠ Limitation: A fuse cannot suppress transient overvoltage events such as lightning or switching surges.

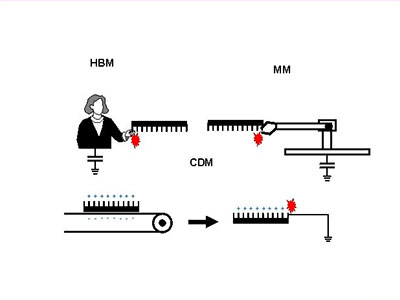

Varistor (MOV) in Overvoltage Protection: Working Principle and Selection Guide

A varistor (MOV) is dedicated to overvoltage protection, connected in parallel to the circuit. It exhibits a non-linear voltage-current characteristic: high resistance at normal voltage, and low resistance during surges, clamping voltage to a safe level.

Varistor Voltage and Clamping Voltage

- Varistor Voltage (Vv): Voltage across the MOV at 1 mA test current.

- Clamping Voltage (Vc): Peak voltage under surge current (e.g., 8/20 µs waveform).

Maximum Allowable Voltage

The maximum RMS or DC voltage that can be continuously applied without degrading performance.

Maximum Surge Current Capability

Defines the peak current the MOV can withstand under standard surge tests.

⚠ Limitation: MOVs degrade with repeated surges and may short under prolonged overvoltage if no upstream current-limiting device is used.

Fuse vs Varistor: Key Differences in Circuit Protection

- Protection Type: Fuse → Overcurrent, Varistor → Overvoltage.

- Circuit Position: Fuse in series, MOV in parallel.

- Response Time: Fuse (delayed, thermal); MOV (instant, nanoseconds).

- Maintenance: Fuse must be replaced after operation; MOV can operate multiple times but ages gradually.

👉 Fuses and MOVs are complementary, not interchangeable.

How Fuses and MOVs Work Together for Surge Protection

- Normal Operation: Fuse carries current; MOV stays inactive.

- Transient Surge: MOV clamps voltage and diverts surge energy; fuse remains intact.

- Severe Overvoltage or MOV Failure: If MOV shorts, the fuse disconnects the circuit, preventing fire hazards.

Case Study: Fuse and MOV Protection in LED Driver Circuits

For LED drivers complying with IEC 61000-4-5 surge immunity:

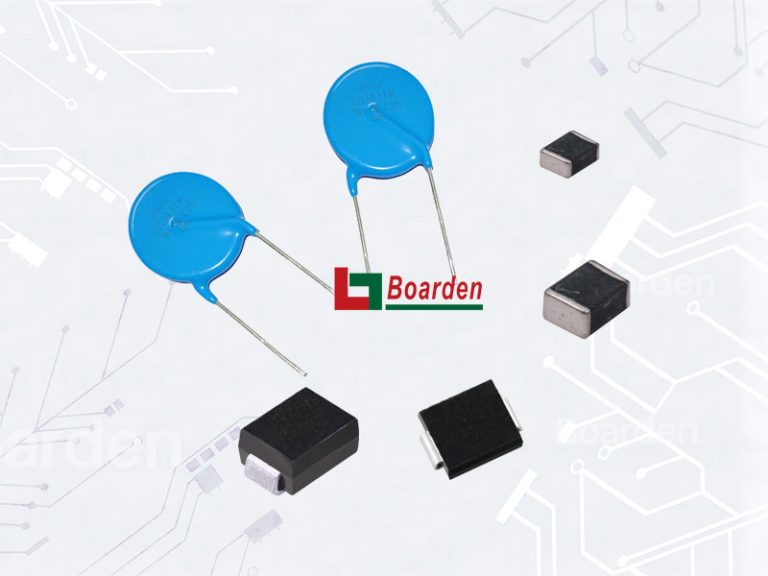

- MOV Selection: Choose a device with maximum allowable voltage above mains fluctuation and clamping voltage below downstream IC limits (e.g., Boarden CMS Series MOV).

- Fuse Selection: Use a slow-blow fuse rated for normal current, with I²t higher than the MOV surge energy, avoiding nuisance tripping (e.g., Boarden SMD Time-Lag Fuse).

✅ This design ensures LED drivers survive everyday surges while disconnecting safely under severe faults.

Boarden Circuit Protection Solutions

With 20+ years of experience in electronic protection, Boarden provides a complete product portfolio:

- SMD Fuses

- SMD MOVs (CMS/MLV Series)

- TVS Diodes

- GDT Gas Discharge Tubes

- ESD Protection Components

Boarden engineering team supports customers with component selection, parameter matching, and compliance certifications, delivering reliable protection for LED lighting, automotive electronics, motorcycles, and industrial power systems.

For more circuit protection resources or to speak directly with our engineers, contact us join Boarden technical discussion group.